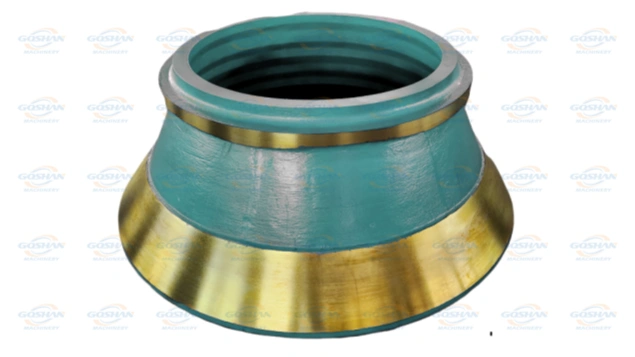

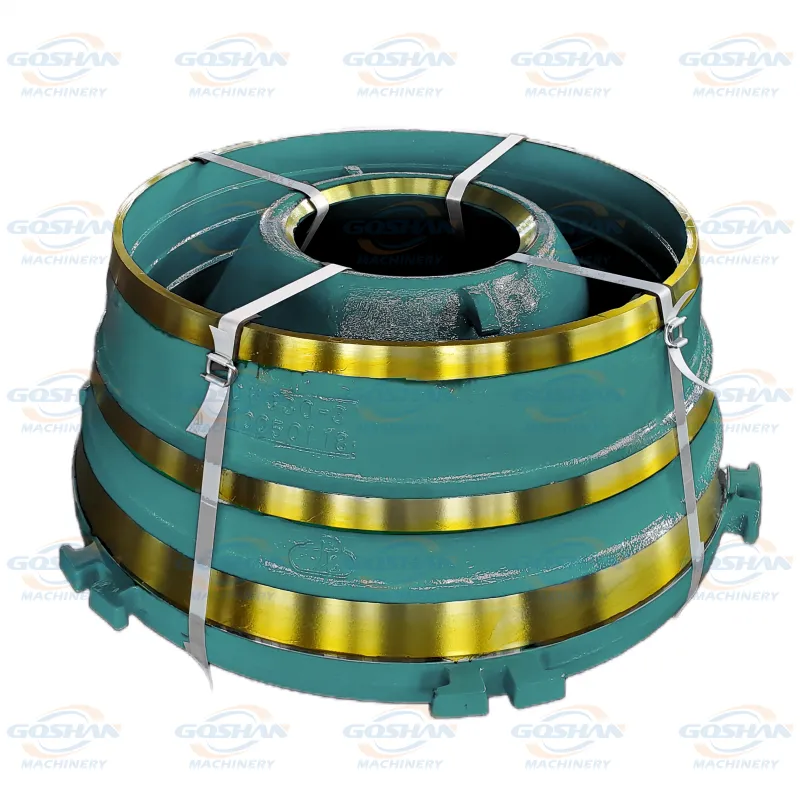

Goshan’s Mantle

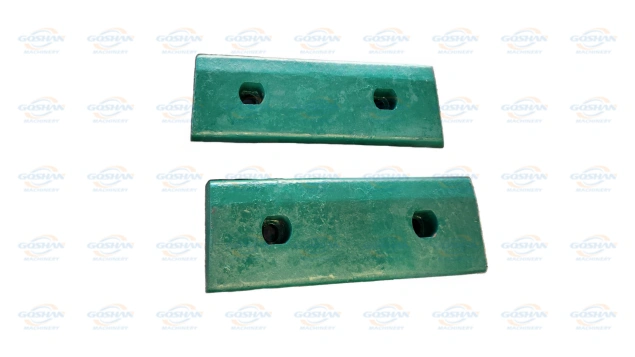

As the core component of the cone crusher, the crushing wall directly determines the working efficiency and quality of the finished product. The crushing wall produced by our company is made of high manganese steel/alloy steel. It not only has excellent wear resistance, but also can withstand high-intensity impact. It is particularly suitable for processing high-hardness materials such as granite and basalt. The precisely designed curved surface structure can achieve uniform force on the material in the crushing chamber, and cooperate with the mortar wall to form an efficient crushing area, with excellent particle shape and significantly improved yield.

In terms of production technology, we use three core technologies:

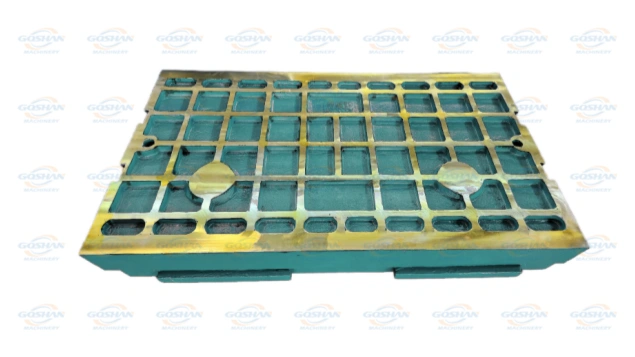

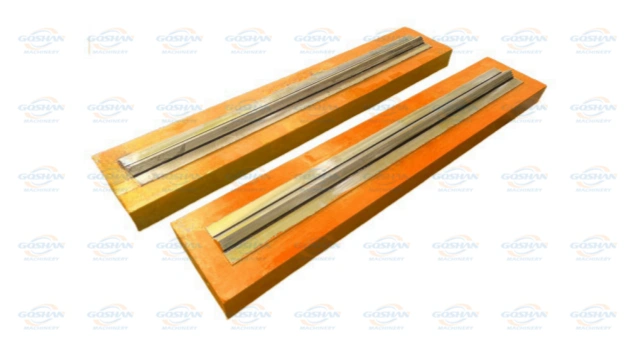

Precision casting: The mold made by three-dimensional modeling ensures that the wall thickness error is controlled within ±2mm

Gradient heat treatment: The original quenching process makes the surface hardness of the material reach HRC58-62, and the internal toughness is maintained

Actual use data shows that our crushing wall is compared with conventional products:

• The processing capacity is increased by 15-20%

• Energy consumption is reduced by about 8-12%

The service life is extended by more than 20%

Supports domestic and foreign mainstream brand models. Free mapping services can be provided, and non-standard parts can be customized according to customers’ existing equipment. Free replacement for non-human damage during the warranty period, 24-hour technical support at any time.

If you are looking for a more cost-effective broken wall solution, please feel free to contact our GOshan team for a customized solution.

.png)